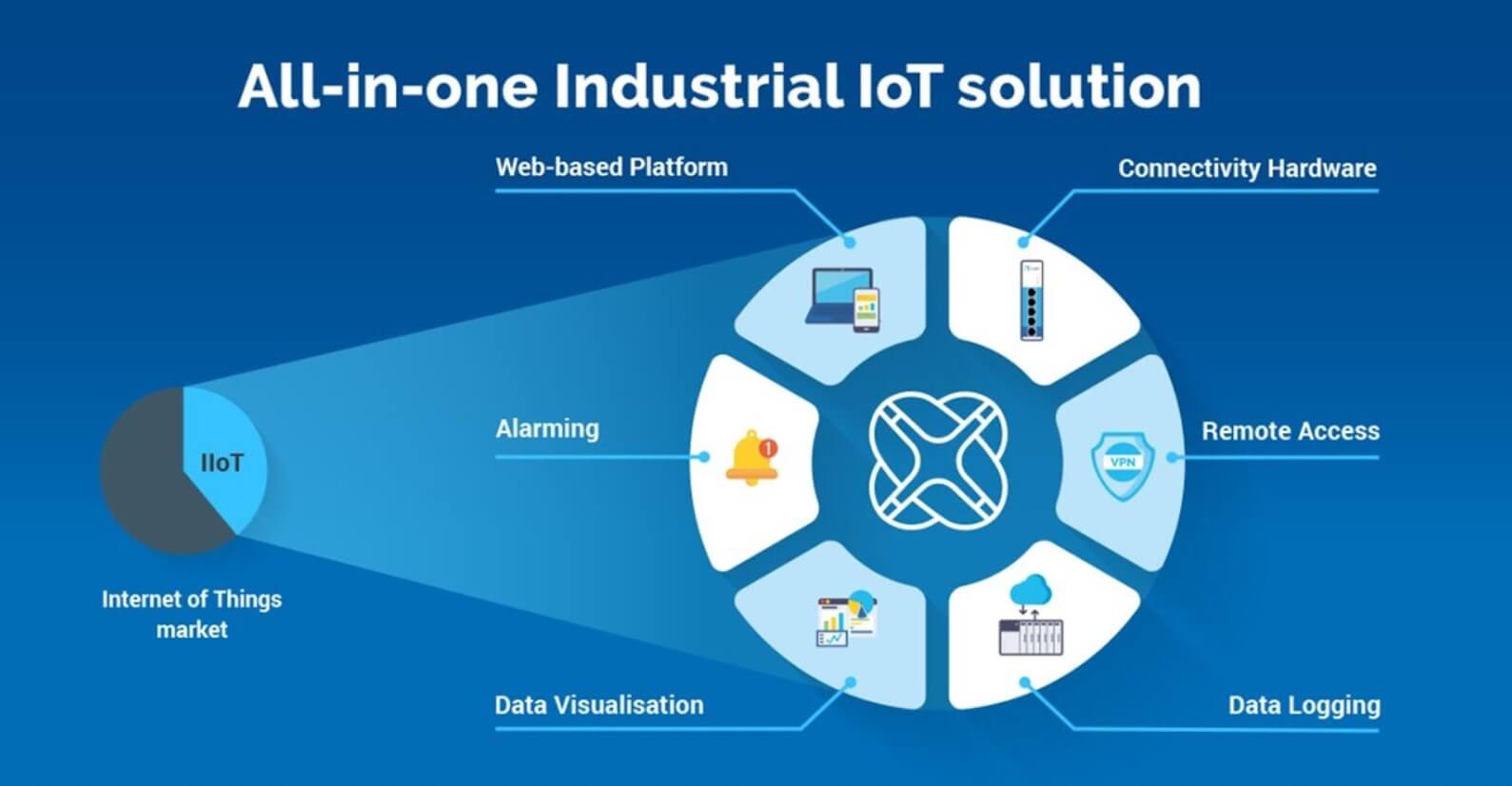

Top 10 Industrial IoT Applications with Real-life Examples

The Industrial IoT Applications has revolutionized the manufacturing and industrial sectors, driving efficiency, safety, and productivity. By connecting machines, sensors, and devices through the internet, IIoT facilitates real-time data collection and analysis, enabling smarter decision-making.

This article explores the top 10 Industrial IoT Applications with real-life examples, showcasing how industries are leveraging this technology to their advantage.

1. Predictive Maintenance

What is Predictive Maintenance?

Predictive maintenance involves using IIoT sensors and data analytics to predict when equipment is likely to fail, allowing for timely maintenance and reducing unplanned downtime. This approach not only enhances the lifespan of machinery but also minimizes maintenance costs.

Real-life Example: General Electric (GE)

General Electric has implemented predictive maintenance across its operations. By using sensors to monitor the health of its jet engines, GE can predict potential failures before they occur. This proactive approach has reduced maintenance costs by up to 30% and increased aircraft availability.

2. Asset Tracking and Management

What is Asset Tracking and Management?

Asset tracking and management involve using IIoT devices to monitor the location and condition of assets in real-time. This ensures efficient use of resources, reduces losses, and improves inventory management.

Real-life Example: Caterpillar

Caterpillar, a leading manufacturer of construction machinery, uses IIoT for asset tracking. Their equipment is fitted with sensors that provide real-time data on location, usage, and condition. This has improved fleet management and optimized maintenance schedules, leading to significant cost savings.

3. Smart Energy Management

What is Smart Energy Management?

Smart energy management utilizes IIoT to monitor and control energy consumption in industrial facilities. By collecting data from various energy-consuming devices, it helps in optimizing energy use, reducing waste, and lowering costs.

Real-life Example: Siemens

Siemens employs IIoT in its smart grid solutions to optimize energy use in industrial plants. Their systems can predict energy demand and adjust supply accordingly, reducing energy waste and lowering operational costs by up to 15%.

[embed]https://youtu.be/8vm6ZnJNxZc[/embed]

4. Quality Control

What is Quality Control in IIoT?

IIoT enhances quality control by providing real-time data on production processes. Sensors monitor various parameters, ensuring products meet quality standards and identifying defects early in the manufacturing process.

Real-life Example: Hitachi

Hitachi uses IIoT for quality control in its manufacturing processes. By integrating sensors that monitor every stage of production, they can detect deviations from quality standards immediately. This has resulted in a significant reduction in defective products and improved overall product quality.

5. Supply Chain Optimization

What is Supply Chain Optimization?

IIoT optimizes the supply chain by providing real-time visibility into the movement of goods. This enables better inventory management, reduces delays, and improves the coordination between suppliers and manufacturers.

Real-life Example: Amazon

Amazon leverages IIoT to streamline its supply chain operations. Sensors and automated systems track inventory levels and movement in real-time, ensuring efficient stock management and timely deliveries. This technology has helped Amazon maintain its competitive edge in logistics.

6. Remote Monitoring and Control

What is Remote Monitoring and Control?

Remote monitoring and control involve using IIoT to oversee and manage industrial operations from a distance. This is particularly useful for hazardous environments or locations that are difficult to access.

Real-life Example: Shell

Shell uses IIoT for remote monitoring of its oil rigs. Sensors installed on the rigs transmit real-time data to a central control center, allowing engineers to monitor conditions and make adjustments remotely. This has improved safety and reduced the need for on-site personnel.

7. Environmental Monitoring

What is Environmental Monitoring?

Environmental monitoring with IIoT involves using sensors to track environmental conditions such as air quality, temperature, and humidity. This is crucial for industries that need to maintain specific environmental standards.

Real-life Example: Nestlé

Nestlé utilizes IIoT for environmental monitoring in its food processing plants. Sensors track temperature and humidity levels to ensure optimal conditions for food safety and quality. This technology has helped Nestlé maintain high standards of hygiene and product quality.

8. Automation and Robotics

What is Automation and Robotics in IIoT?

Automation and robotics in IIoT involve using connected robots and automated systems to perform repetitive or hazardous tasks. This increases productivity and safety while reducing labor costs.

Real-life Example: Tesla

Tesla's manufacturing plants are a prime example of IIoT-driven automation. Robots and automated systems perform tasks such as welding, painting, and assembly, all coordinated through IIoT networks. This has significantly increased production efficiency and product consistency.

9. Safety and Security

What is Safety and Security in IIoT?

IIoT enhances safety and security by providing real-time monitoring and alerts for potential hazards. It can also integrate with safety systems to automate responses to emergencies.

Real-life Example: Honeywell

Honeywell uses IIoT to improve safety in industrial environments. Their connected safety solutions monitor worker health, environmental conditions, and equipment status. In case of a potential hazard, the system can alert workers and management immediately, reducing the risk of accidents.

10. Enhanced Customer Service

What is Enhanced Customer Service in IIoT?

Enhanced customer service through IIoT involves using data from connected devices to offer better support and personalized services to customers. This can lead to increased customer satisfaction and loyalty.

Real-life Example: Rolls-Royce

Rolls-Royce uses IIoT to provide superior customer service for its aircraft engines. By monitoring engine performance in real-time, Rolls-Royce can offer predictive maintenance services to airlines, reducing downtime and improving reliability. This proactive approach has set new standards for customer service in the aviation industry.

Conclusion

The Industrial Internet of Things (IIoT) is transforming industries by providing innovative solutions to long-standing challenges. From predictive maintenance to enhanced customer service, the applications of IIoT are vast and impactful. Companies like General Electric, Caterpillar, Siemens, and Tesla are leading the way, demonstrating the immense potential of IIoT in real-world scenarios. As IIoT technology continues to evolve, we can expect even more revolutionary applications that will drive further efficiencies and innovations in the industrial sector.

By embracing IIoT, industries can not only improve their operational efficiency but also gain a competitive edge in an increasingly digital world. Whether through smart energy management, supply chain optimization, or advanced automation, the benefits of IIoT are clear and compelling. As more companies adopt these technologies, the future of industry looks set to be smarter, more efficient, and more connected than ever before.